Home / EV Charging News / Fleet EV Charging: 5 Common Problems and Solutions

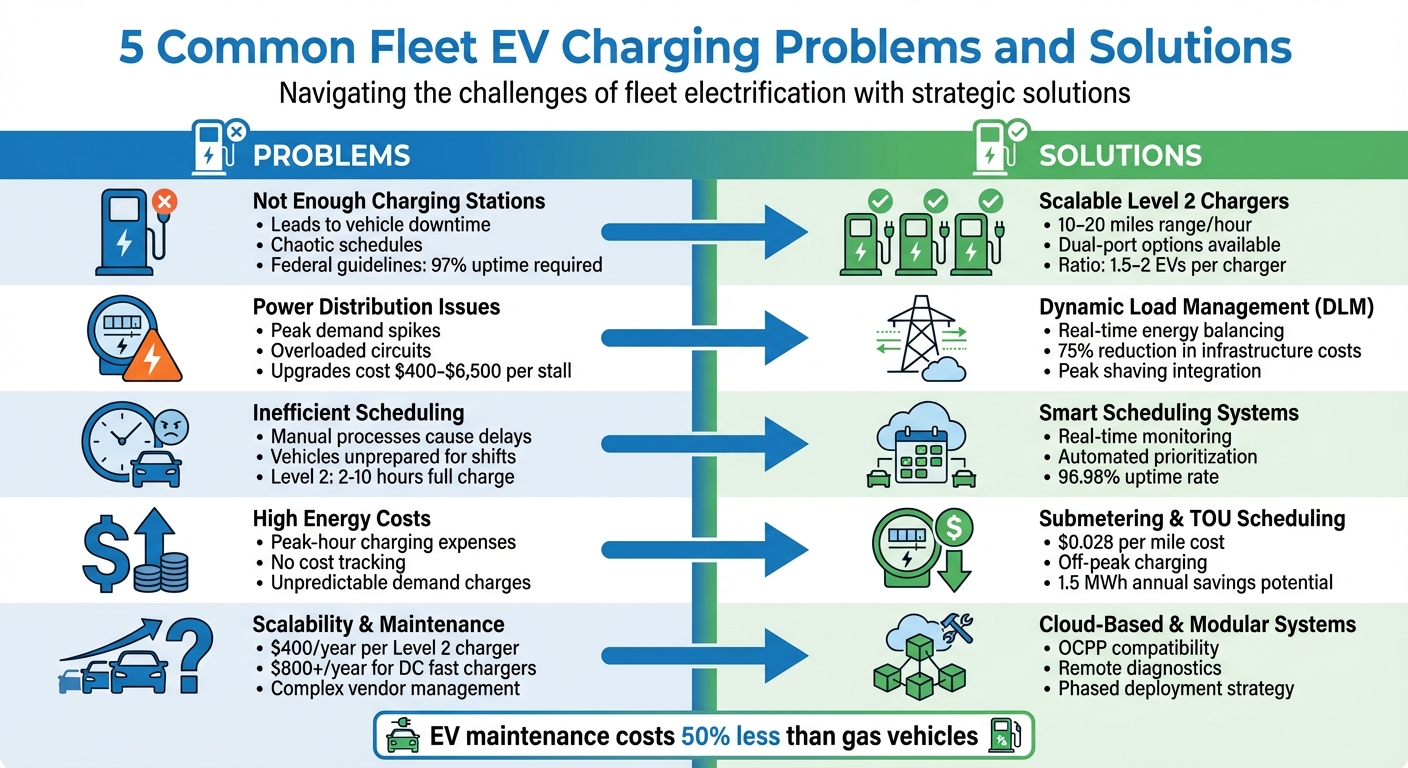

Transitioning to electric vehicle (EV) fleets can save money, improve efficiency, and meet regulatory demands. But it also comes with challenges, especially around charging infrastructure. Here’s a quick breakdown of the five most common issues businesses face and how to solve them:

Key Takeaway: Careful planning, smart technology, and scalable solutions can streamline the transition to EV fleets, ensuring efficiency and cost savings.

5 Common Fleet EV Charging Problems and Solutions

A lack of charging stations can bring fleet operations to a standstill. Instead of being on the road, vehicles often sit idle, waiting for a charger. This creates chaotic charging schedules, making it difficult to prioritize which vehicles get charged first, wasting both time and energy.

Take a fleet of 20 EVs with only 10 charging stations. Half the fleet is left competing for access, leading to extended wait times and reduced efficiency. The problem worsens with slower Level 1 chargers, which only add 2–5 miles of range per hour. In these cases, vehicles may not fully charge overnight, further delaying operations. Additionally, this shortage puts strain on your power infrastructure, creating bottlenecks that ripple through your entire operation.

The financial impact goes beyond downtime. Adding chargers incrementally is far more expensive than planning for future growth upfront. On top of that, “unmanaged charging” – where vehicles draw power as soon as they’re plugged in – leads to peak demand spikes. These spikes can overload electrical systems and result in hefty demand charges from utility companies. This instability can jeopardize facility power, making the need for scalable charging solutions even more urgent.

Federal guidelines recommend 97% uptime for charging stations to maintain fleet reliability. When chargers are in short supply, even a single outage can disrupt schedules. For larger fleets with adequate dwell times, a ratio of 1.5 to 2 EVs per charger is both efficient and cost-effective. However, achieving this balance requires careful planning from the outset.

The solution lies in forward-thinking planning and smart equipment choices.

The first step is selecting the right chargers while planning for future growth. Level 2 chargers are ideal for most fleet needs, offering 15–40 miles of range per hour at a fraction of the cost of DC fast chargers. For fleets with overnight charging windows, this speed is sufficient to fully recharge vehicles between shifts.

CyberSwitching offers a range of fleet-focused chargers, including the CSE1 ($1,190–$1,320), CSE3 ($1,250–$1,390), and CSE4 (starting at $2,050). These chargers are OCPP-compatible, meaning you’re not tied to a single software provider, giving you flexibility as your needs evolve.

“A strategic approach that allows a fleet to solve for their immediate goals while providing flexibility to adapt to an uncertain future is critical to successfully navigating this transition.”

- Patrick Couch, Senior Vice President at TRC.

Features like built-in RFID enable driver-specific access and usage tracking. This prevents unauthorized use and provides data to help optimize charging schedules.

For growing fleets, dual-port chargers like the Dual 80A CSE4, priced at $3,550, can charge two vehicles from one installation point. These modular systems allow for easy expansion without major infrastructure changes.

Investing in enough charging capacity to cover your fleet’s projected needs over the next five years is a smarter move. While it may require a larger upfront investment, it eliminates the need for repeated construction projects and their associated costs. For instance, in California, nonresidential buildings with 10 or more parking spaces must already have EV infrastructure for at least 6% of those spaces. These requirements will only grow stricter, making long-term planning essential.

When multiple EVs charge at the same time, it can create a surge in energy demand, leading to expensive peak charges and overloaded circuits. Traditional unmanaged charging systems pull full power immediately, which can overwhelm electrical systems and even leave some vehicles without a charge.

Upgrading infrastructure might seem like the logical solution, but it comes with hefty downsides. Utility upgrades can take over six months to complete and cost anywhere from $400 to $6,500 per charging stall. While switching to an EV fleet could save the U.S. federal fleet about $6 billion over 15 years, those savings can quickly disappear if high peak demand charges or costly infrastructure updates eat into the budget. Clearly, a smarter, more efficient approach to power management is essential.

Dynamic Load Management (DLM) offers a smarter way to handle power distribution by constantly monitoring and redistributing energy to balance the load in real time. Unlike static systems that stick to fixed power limits, DLM adjusts charging output based on the actual conditions of the grid and the demands of the building.

“Dynamic Load Management is a game-changer for businesses looking to deploy EV charging infrastructure without overloading electrical systems or incurring excessive costs.”

- Nick Zamanov, Head of Sales

CyberSwitching’s EV master controllers take this concept further by dynamically balancing loads across multiple circuit breakers at a fraction of the cost of full-scale infrastructure upgrades. These systems use rotational charging, cycling power among 4 to 8 EVs at programmable intervals (ranging from 10 to 120 minutes), which maximizes circuit efficiency. This method can slash infrastructure material costs for new facilities by as much as 75%.

The system also integrates seamlessly with your Building Energy Management System (BEMS) to implement what’s known as peak shaving. When your building’s HVAC, lighting, or other systems are drawing high amounts of power, the controller temporarily reduces EV charging. As building power demands decrease, EV charging ramps back up. This ensures your facility stays within its power limits while still providing adequate charging for vehicles.

You can also customize smart prioritization rules to allocate power based on specific needs – such as the state of charge, departure schedules, or operational priorities. For instance, vehicles that need to leave earlier can be prioritized to ensure they’re charged and ready to go when required.

Additionally, all CyberSwitching chargers support the Open Charge Point Protocol (OCPP), allowing for remote monitoring and control. This flexibility makes it easy to scale your infrastructure as your needs grow. Integrated submetering technology provides detailed insights into energy usage, helping you fine-tune charging schedules for maximum efficiency.

Managing an EV fleet without access to real-time battery and charging data can lead to serious inefficiencies. Manual scheduling often results in vehicles sitting idle or being unprepared during peak usage times. Efforts to delay charging to off-peak hours in order to reduce Time-of-Use (TOU) charges can leave vehicles with insufficient range for their next shift. Additionally, when multiple EVs charge at the same time, it can strain a facility’s electrical capacity, potentially requiring costly infrastructure upgrades or leaving some vehicles without a full charge.

Matching the right charger to the vehicle is also critical. For example, Level 2 chargers add about 25 miles of range per hour, but they take 2 to 10 hours for a full charge, making them unsuitable for vehicles with high usage demands. On the other hand, DC Fast Chargers can charge a vehicle to 80–90% in just 20–30 minutes, but they come with significantly higher costs.

These inefficiencies highlight the need for a smarter approach to scheduling and charging, one that ensures fleet reliability without unnecessary downtime.

A Charging Management System (CMS) provides a data-driven solution to these scheduling challenges. By automating power distribution based on vehicle needs and departure schedules, a CMS removes the guesswork from fleet management. When paired with real-time telematics through API connections, these systems use key data – such as battery state of charge (SoC), vehicle location, and route requirements – to create optimized charging schedules.

For instance, CyberSwitching’s hardware, integrated with the CSMS software, offers advanced features like real-time analytics, charging reservations, and automated prioritization. The system uses smart algorithms to prioritize vehicles with low SoC or urgent departure times, even redistributing power from nearly charged vehicles to those that need it most. This ensures that all vehicles are ready when they’re needed.

Cloud-based dashboards for remote monitoring add another layer of efficiency. They allow fleet managers to quickly identify and address hardware issues, minimizing unexpected downtime. Take the CyberSwitching CSE1 charger as an example – it boasts an uptime rate of 96.98% and includes remote access control with RFID authentication, making the charging process seamless and secure.

Charging electric vehicle (EV) fleets during peak hours can lead to soaring electricity bills. Without the right tracking tools, businesses often struggle to pinpoint where their energy dollars are going. This lack of visibility makes it difficult to identify waste or find ways to cut costs effectively.

Another challenge is separating fleet charging expenses from those of employees or visitors. Without proper systems in place, businesses face inaccurate cost allocation and may miss out on potential revenue. This becomes even more critical for organizations needing detailed energy data to comply with regulations like the Energy Independence and Security Act of 2007.

Demand charges add another layer of complexity. These fees, based on the highest power draw during a billing period rather than total energy usage, can skyrocket when EV charging overlaps with peak building operations. For businesses without insight into their charging patterns, these charges result in unpredictable and often steep monthly bills.

Additionally, the absence of cost-tracking tools makes it impossible to recover expenses when non-fleet vehicles use the charging stations. What could be a revenue-generating asset instead turns into a financial burden. Addressing these rising costs requires a more precise and efficient management approach.

Submetering systems offer the accuracy needed to manage EV charging expenses effectively. By isolating EV charging loads from general building electricity use, these systems enable businesses to monitor specific circuits. This is essential for benchmarking energy performance and ensuring EV charging doesn’t negatively impact overall building energy ratings.

Networked submeters take this further by uploading data to an Energy Management Information System (EMIS). This allows for real-time tracking and optimization, eliminating manual meter readings. Businesses can also use this granular data to differentiate between fleet vehicle charging and privately owned vehicle (POV) usage – critical for financial reporting and regulatory compliance.

CyberSwitching’s commercial chargers come equipped with metering capabilities and integrated payment systems, offering a complete cost management solution. For instance, the CSE3 charger, certified by the California Type Evaluation Program (CTEP) for billing applications, ensures precise measurements for commercial transactions. Paired with the EPIC software platform, these chargers provide real-time insights into charging activities, energy consumption, and costs.

The benefits don’t stop at tracking. Smart charging systems with Time-of-Use (TOU) scheduling allow fleet operators to charge vehicles during off-peak hours when electricity rates are lower. For example, highly efficient EVs consuming 27 kWh per 100 miles cost about $0.028 per mile based on an average electricity rate of 10.7 cents per kWh. ENERGY STAR-certified 50 kW DC fast chargers can save approximately 1.5 MWh annually, translating to about $1,650 in savings over their lifetime.

Integrating payment systems can also turn charging infrastructure into a revenue source. Businesses can charge users per kilowatt-hour (kWh) or per session, recovering operational costs and potentially generating profit. CyberSwitching’s CSE1 charger includes RFID authentication, making it easy to control access and track individual sessions. For federal agencies, this feature ensures compliance with the FAST Act, which mandates fee collection for POV charging to recover electricity and infrastructure costs.

Scalability is a key factor in ensuring the long-term efficiency of electric vehicle (EV) fleets. As fleets expand, the charging infrastructure has to grow alongside them. This growth often comes with significant challenges. Adding more vehicles means upgrading electrical systems to handle increased power demands, which can lead to higher construction costs. These upfront installation hurdles also pave the way for ongoing issues with maintenance and scalability.

As fleets grow, maintenance becomes more complex. With more chargers in daily operation, wear and tear on the equipment accelerates. For example, station owners might need to budget up to $400 per year for each Level 2 charger and over $800 annually for DC fast charger warranties. Without proper planning, the reliance on proprietary systems can complicate maintenance, driving up costs and potentially sidelining vehicles. Patrick Couch, Senior Vice President of Clean Transportation Solutions at TRC, likens this vendor lock-in scenario to a “spaghetti chart” of communication standards.

Managing charging schedules for dozens – or even hundreds – of vehicles adds another layer of complexity. It’s not just about plugging in; avoiding peak demand charges and ensuring efficient use of infrastructure requires advanced management systems. Without such systems, installations risk becoming redundant, and the infrastructure may struggle to keep up with advancements in vehicle technology.

To tackle these challenges, fleet operators need a flexible and forward-thinking charging strategy. Cloud-based management systems are a game-changer here. These platforms provide real-time monitoring and send proactive maintenance alerts, enabling providers to address issues remotely through software or firmware updates. This eliminates much of the guesswork involved in scaling an EV fleet.

Interoperability is another critical factor. Using chargers that are compatible with the Open Charge Point Protocol (OCPP) ensures that hardware and software can work seamlessly across various systems, reducing the risk of vendor lock-in. For instance, CyberSwitching’s chargers support OCPP, giving fleet operators the freedom to adapt their systems without needing a complete overhaul.

Modular charger designs also help manage costs effectively. Take dual-port stations like the CyberSwitching CSE3 dual, priced at $3,490 – these reduce per-port installation expenses and limit the need for extensive electrical upgrades. For larger fleets, maintaining a ratio of 1.5 to 2 EVs per charging port strikes a balance between cost efficiency and ensuring sufficient charging capacity.

A phased deployment strategy is another smart approach. Instead of making a large upfront investment, businesses can align their infrastructure installations with vehicle procurement schedules. This incremental method allows companies to adapt to new technologies and manage capital costs more effectively. CyberSwitching’s scalable solutions, such as the CSE1 priced at $1,190 and the dual 80A CSE4 at $3,550, are well-suited for this gradual expansion strategy.

Finally, remote diagnostics capabilities significantly reduce maintenance response times. Cloud-based systems can detect potential issues before they lead to major downtime. Many problems can even be resolved through cloud-to-cloud firmware updates, ensuring minimal disruption. This proactive approach helps maintain high uptime standards, which are critical for commercial fleet operations, while keeping maintenance costs under control as the infrastructure scales.

Shifting to an electric fleet comes with its share of hurdles, but each challenge has a practical fix. For example, the lack of charging stations? That can be tackled with scalable, modular chargers. Power distribution concerns? Load management systems efficiently distribute energy across vehicles without the need for costly electrical upgrades. And downtime? Smart charging software optimizes schedules based on routes and off-peak electricity rates to keep things running smoothly.

Managing costs is another critical piece of the puzzle. Tools like off-peak charging can significantly cut operational expenses. In fact, maintaining electric vehicles costs about 50% less than their gas-powered counterparts. To address scalability and maintenance worries, cloud-based management platforms and OCPP-compatible chargers allow for remote diagnostics and keep you from getting locked into a single vendor.

Planning for future growth is essential to avoid repeated construction expenses. CyberSwitching’s solutions are designed to grow with your fleet, offering the flexibility you’ll need as your operations expand.

With a proven track record of national deployments, reliability is at the core of what we do. Partnering with the right solutions provider makes the transition to electric fleets a seamless process.

To gear up for the growth of EV fleets, businesses need to focus on building charging infrastructure that can scale and adapt. This means designing systems that not only meet current needs but can also handle more vehicles and higher power demands in the future. Planning for additional charging stations and ensuring the system is ready for expansion is a smart move.

Using smart charging solutions is another key step. These systems help manage energy use efficiently, prevent grid overloads, and adjust charging schedules to match fleet demands. Pairing this with data-driven tools like telematics can offer valuable insights into charging habits and usage patterns, helping businesses plan for capacity upgrades before they become an issue.

It’s also important to consider operational strategies, such as return-to-base charging for fleets that come back to a central location or on-route charging for vehicles that travel longer distances. By combining scalable infrastructure, intelligent energy management, and data insights, companies can seamlessly grow their EV fleets while keeping operations smooth and efficient.

Dynamic Load Management (DLM) brings several advantages to fleet EV charging. By smartly distributing power among charging stations, it ensures energy is used efficiently and helps prevent your electrical system from being overwhelmed. This creates a smoother and more dependable charging experience for your fleet.

Another benefit of DLM is its ability to help cut down on operational costs. By adjusting charging times based on real-time energy demand and availability, it can lead to noticeable savings on electricity bills – especially when paired with off-peak charging. Plus, DLM plays a role in maintaining grid stability, making it easier to expand your charging network as your fleet grows, all without sacrificing performance or reliability.

Cloud-based systems play a key role in improving EV fleet charging by offering real-time tracking, centralized management, and smarter charging strategies. With these tools, fleet managers can monitor charging progress, vehicle locations, and energy consumption from anywhere, making it simpler to plan charging schedules and cut down on operational expenses.

These platforms also enable smart charging, which adjusts charging times based on electricity prices, grid demand, and vehicle needs. This not only helps fleets dodge high energy costs but also prevents grid overloads and ensures power is distributed efficiently. On top of that, cloud-based systems make it easier to coordinate between fleet vehicles, charging stations, and utility providers, allowing for smooth scaling as fleets expand.

By automating tasks and providing useful data insights, these systems help streamline operations, reduce costs, and support the efficient management of commercial EV fleets.